MSU students build device to help NASA study clogged pipes on space station

When Montana State University researcher Stephan Warnat wanted to help solve a longstanding problem on the International Space Station, he turned to a group of four mechanical engineering majors.

During a recent Montana Biofilm Meeting hosted by MSU's Center for Biofilm Engineering, Warnat learned from NASA scientists that microbial buildup sometimes clogs the space station's water pipes — a demanding challenge for astronauts to fix. A specialist in tiny sensors used to measure, among other things, water quality, Warnat wanted to study how the microbes grow. He just needed a research device that could simulate the microgravity of low Earth orbit.

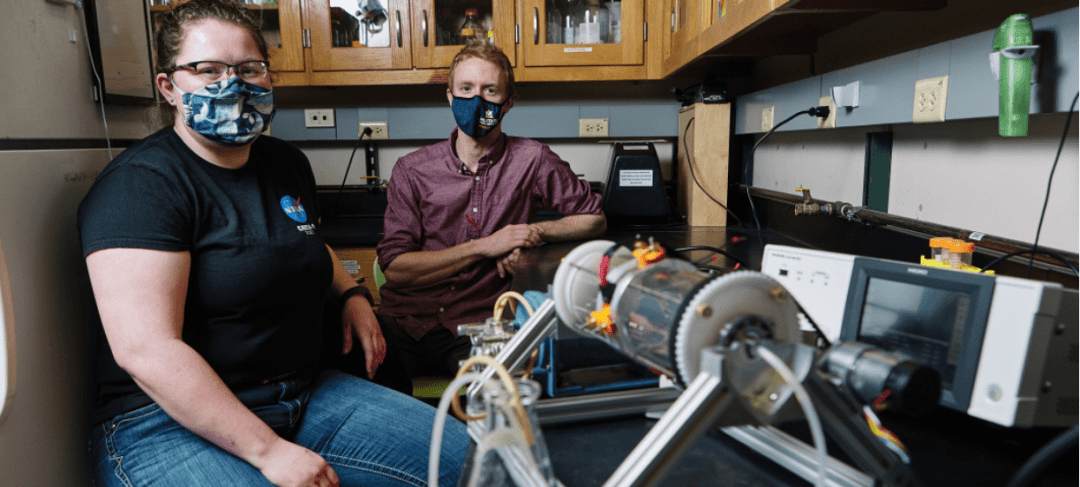

That's where the students came in. Working as a team over two semesters, they designed and built a working prototype of the device as their "capstone" project, the task that all engineering seniors must complete in order to graduate. The team included four seniors in mechanical engineering: Spencer Ball, Ryan Davis, Haley Ketteler and Connor Tappe. Ball, Davis and Tappe graduated in November.

Like a small rock tumbler, the tool they made consists of a section of pipe that slowly rotates to prevent microbes from settling with gravity. Fluid is passed through the pipe, and embedded sensors measure biofilm behavior.

"It's really, really cool," said Warnat, an assistant professor in the Department of Mechanical and Industrial Engineering in MSU's Norm Asbjornson College of Engineering.

The students presented the device to Warnat's collaborators at NASA in the fall. NASA is very pleased with the design and will use the device in future research efforts, Warnat said. In the meantime, NASA issued Warnat's research team a $100,000 grant that will support using the device to develop sensors for detecting biofilm growth in the space station's plumbing. Warnat will lead the project with MSU's Christine Foreman, professor in Department of Chemical and Biological Engineering.

Warnat said he wasn't surprised by the project's success because he had previously worked with MSU engineering students on four other capstone projects. The projects are structured around design challenges posed by private industry, national labs, organized events like the RoboSub competition and by university faculty.

"What I like is getting a group of young engineers who actually have a lot of experience but who have no idea about my research and come with open eyes to develop something new," Warnat said. "I actually had something completely different in mind for this device, but what they made is perfect."

MSU's engineering seniors have the technical expertise to construct things that faculty wouldn't be able to make themselves and that would be prohibitively expensive to purchase, according to Warnat. "Our students are well trained in our machine shop," which includes state-of-the-art, precision tools for cutting and shaping metal and other materials, he said.

For capstone team member Davis, the project was valuable experience with seeing a months-long, intensive design task through to the end.

"It put to work a lot of what we've learned in our classes," said Davis, who machined some of the components on a lathe and now works at a local manufacturing design business. Warnat "did a good job of presenting the project as something that was really worthwhile to him and other people, so we were motivated to work on it," he said.

Ketteler said the project harnessed her passion for space engineering and dovetailed with a virtual summer internship with NASA's Langley Research Center.

"It really challenged our thinking," said Ketteler, who handled all the electronics for the device. Warnat "gave us a starting point with an idea of what he wanted, but said, from then on, we had to design it and make the final decisions."

Working with a capstone team is a great opportunity for MSU faculty to advance a research idea and get it to a point where they can secure grant funding, according to Warnat, an associate faculty member of the Center for Biofilm Engineering. "This was a really good group," he said. "They didn't need a lot from me."

According to Robb Larson, associate professor of mechanical engineering and a coordinator for capstone projects, there's always a need for new capstone sponsors, and anyone interested in sponsoring a project can contact him.